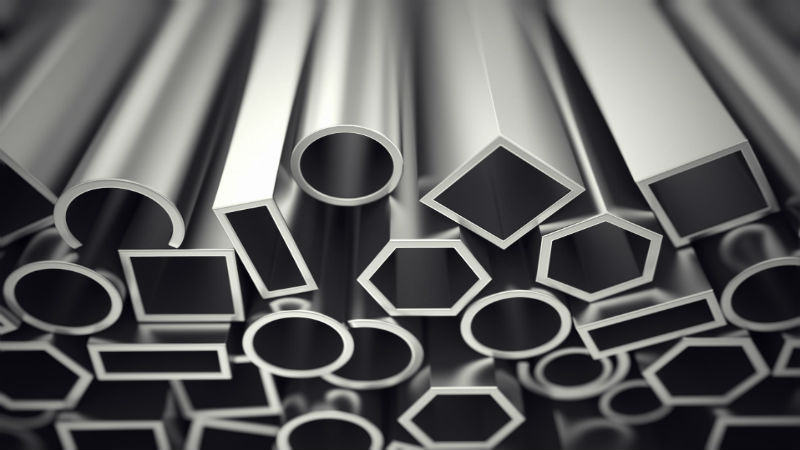

Aluminum Extrusion Shapes

When you need custom aluminum extrusion shapes, you need a dependable machining company. Otherwise, you cannot rely on the products they supply, but that is not the case when you order from here. For decades, they have made custom extrusions using 6061, 7075, and 7050 alloys.

Round Bar

Does your business need a regular supply of 6061 T6511 alloys? If so, then you must work with a supplier that can match Hydro specifications. Furthermore, your company can use these extrusions to make couplings, fittings, or bearings. Whether you work on the railroad or in aerospace, these are ideal casts.

The 6061 alloy possesses a unique combination of malleability, ductility, and strength. In addition, its lightweight design makes it superb for use in durable applications. When ordered custom, the tolerances are kept close to +/-0.005.”

Likewise, you can expect the final order to have an RMS finish as low as 32*.

Rectangular

Rectangular bars vary in size, but they usually have a density of 0.98. The standard length of flat bar stock is 12 feet, and they have tight tolerances when machined. Moreover, they can be machined using band saws if needed, making them widely variable.

Square Bar

Square bar extrusions are available in many sizes, and you can order them using many alloys. Whether you work in aerospace, construction, or medical, these custom extrusions are perfect. Since they are both durable and lightweight, they are useful in tons of cases.