Heat treatment is a vital component of the metals and steel industry. Treating with heat gives metal important properties like strength and resistance to corrosion, and this requires temperatures that are extremely high. In fact, temperatures sometimes need to be in excess of 1800 degrees Fahrenheit, and a vacuum heat treat furnace may be the perfect equipment for this process.

What is a Vacuum Furnace?

When steel is heated in a normal environment it is subject to contamination from the atmosphere. Also, heat transfer throughout the steel (by convection) can affect many heat treatment processes. To solve this problem, a vacuum furnace pumps oxygen from the chamber. This is done with special vacuum pumps in an airtight environment. This seals the furnace and lowers the atmospheric pressure, and the process comes with many advantages.

• Very high temperatures can be achieved and with even heating. In other words, a section of metal in the furnace is heated uniformly, and this is vital for steel heat treatment methods.

• Temperature control can be obtained within a small area.

• Contamination is very low because oxygen, carbon, and many other gasses are not present in the oven chamber. Normally, when steel is heated it rapidly oxidizes, and this is not good for the metal. Without oxygen (in a vacuum) this does not occur.

• A vacuum allows for rapid quenching or cooling of the steel. During the quenching process, an inert gas is circulated throughout the oven. The gas can be highly pressurized in a vacuum environment before it is passed into the heated area. This allows for efficient heat removal.

Uses for Vacuum Heat Treatment Furnaces

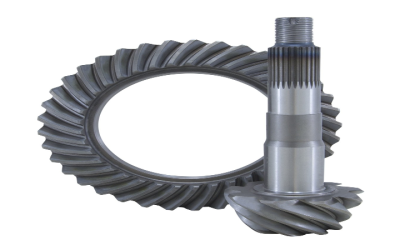

Vacuum heat treatment is often used to create steel alloys. Alloys are added to steel to increase or decrease specific properties and, of course, heat treatment is essential.

Vacuum carburizing is a special process in which carbon is added to steel. During the process, gas like acetylene is placed into the vacuum oven, and it separates into base elements like hydrogen and carbon. This allows carbon to become infused into the steel.

Vacuum ovens are also used for brazing. This is a method for joining two or more metals by melting another metal in between them.

Gas or Electric Heat?

For many years, electric elements were the preferred method of vacuum oven heating. However, many companies are turning to gas for its benefits. Natural gas allows for more rapid heating, and the heat is more uniform or even than electricity. This allows for the creation of many complex steel parts.

ECM USA is a major supplier of quality vacuum heat treat furnace products and service to the aerospace, automotive, arsenal, and steel making industries, as well as many other sources. To see what we can for your company, visit us online today at http://ecm-usa.com/.