While steel may be the most used metal in the world, aluminum is now a close second with applications in everything from the aerospace industry to robotics. With its high strength to weight ratio and natural corrosion resistance, it has also become a key structural component in buildings, vehicles, trailers and in all types of machinery and equipment.

Applications and Uses

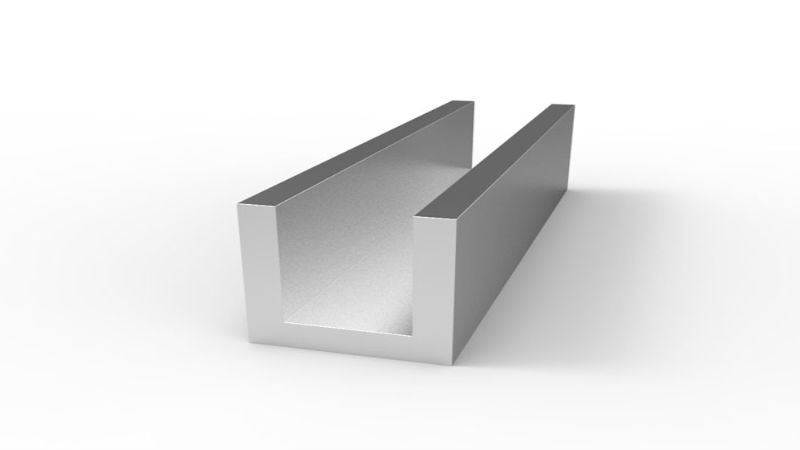

Aluminum rectangular bar can be used on all of these applications. The various aluminum alloys all have their own unique properties that make them the best choice for various applications. Strength, weight, stress resistance, finishing, working and welding will all be factors to consider when choosing the correct alloy of aluminum rectangular bar.

To provide a general overview of the most common of the different alloys and their properties, the following list is a very simple guideline. It will be critical to consider the complete needs for the bar including the environment where it will be used before making the final choice.

2024 aluminum – most commonly used when higher strength requirements are a primary concern. This alloy has copper as the highest percentage of the alloying ingredients. The higher levels of copper also make it more likely to experience corrosion, so it is often clad to limit the effects of the copper. While not weldable, it has very high fatigue resistance and is often used on various components in the aerospace industry.

6061 aluminum – this is the go-to alloy for most applications. It is very strong and naturally resistant to corrosion. It can be welded and it is considered to be relatively easy to machine. This is also an alloy that can be heat treated and it can also go through anodization to provide a very effective protective finish

7075 aluminum – typically used for aircraft and the aerospace industry, this is a specialized type of alloy. It uses both copper and zinc as the main alloying ingredients, so it is high in corrosion resistance as well as machinability. The 7075 alloy is considered to be as strong as many of the mild steels.

Choosing the right alloy for your aluminum bar needs is important. Take the time to consider the options as well as the specific properties you require for the application. If you aren’t sure, talk to an aluminum supplier and discuss your options before making a final choice.