For any type of fabrication or production industry, having top suppliers for all materials required will be an important step in your business. As the plate is typically used in construction and fabrication as well as for tooling and jigs, finding a supplier with the on-hand inventory you need as well as the right size of plate is essential.

Ideally, choose aluminum plate suppliers that are the actual fabricators and not a third-party vendor. This allows you to have the comfort of knowing the quality of the plate will be consistent across orders and deliveries. When working with a metal supply shop, there may be various quality and quantities of aluminum plate included even in a single order, which can be problematic when tight tolerances and specific standards are required.

Aluminum Only

Many large volume metal supply companies deal in all kinds of metals. This can cause a problem as aluminum requires specific types of storage, packing and transportation requirements.

Many general metal suppliers don’t handle aluminum plate correctly, resulting in plate that has surface damage before it even arrives. More than just cosmetic, this can become a significant issue for your company.

Quality Control

The top aluminum plate suppliers have an in-house aggressive quality control system. This means that the plate is tested for hardness, flatness, roughness and for tensile and yield strength in an ongoing fashion. These tests are completed throughout the fabrication process, providing a quality, consistent final product.

In addition to quality control, it may be essential for customers to ensure that the aluminum plate suppliers are RoHS (Restriction of the use of certain Hazardous Substances) compliant. This will be essential for the export of materials to the European Union as well as to an increasing number of countries around the world.

Additional Services

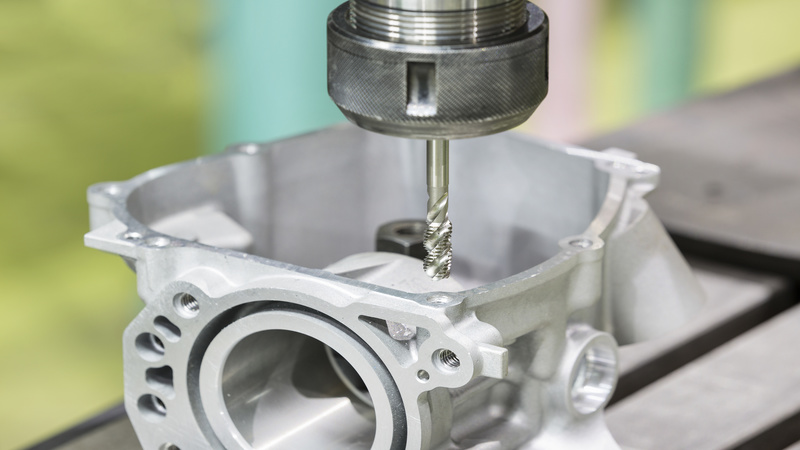

Finding an aluminum supplier that offers the plate you need and additional services is an added perk. These companies can cut to length, finish, machine, mill and provide technical support for the products they provide.

Having these additional services is not just time-saving, it can also be cost saving. By having the parts machined and cut at the aluminum suppliers, you are not paying for shipping of unnecessary aluminum. There is also no waste on-site as there is no need for further processing, which also means no risk of fabrication or machining errors by your own employees.