In almost all types of food and beverage production, stainless steel is the material of choice for various parts, components, and systems. There are many reasons why stainless steel tube fittings, tubes, containers and even pump components are selected over a range of other material options.

Corrosion Resistance

In the not too distant past, a lot of the fittings and tubing used in food and beverage production systems were made of aluminum or even carbon steel. Rust was a problem with carbon steel, while the cracking and pitting present with aluminum created problems for effective cleaning and maintaining the system.

With stainless steel tube fittings, these issues can be eliminated. The surface of the stainless will stay rust-free with the natural corrosion of the various alloys. Additionally, stainless steel is also resistant to pitting and cracking, eliminating the problem found when using aluminum.

Heat and Cold Resistance

Unlike plastics, stainless steel tube fittings are not going to expand and contract or become brittle due to exposure to extreme hot or cold. This can be a significant problem with the use of many types of plastics including PVC and CPVC. This is particularly important in fittings when they are positioned in difficult areas to examine on a routine basis.

Often with plastic fittings, the first signs of problems can be small leaks that go undetected. Then, often rapidly, the deterioration of the fittings starts, resulting in a significant leak in the system that can result in loss of pressure, contamination of the processing systems as well as other factors.

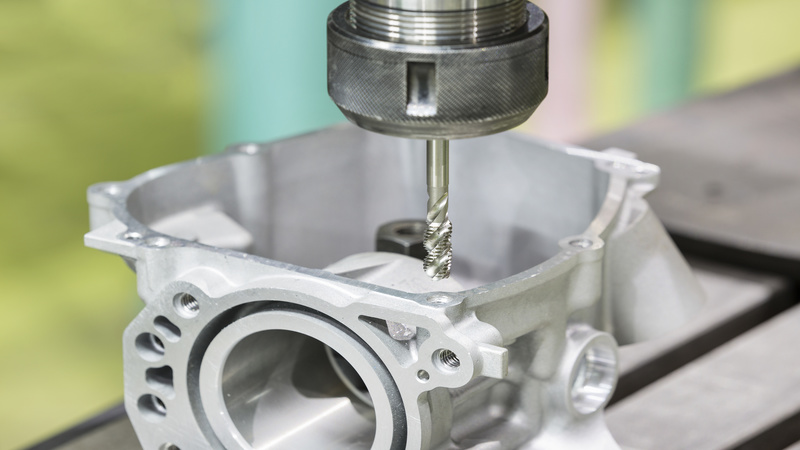

Stainless steel is also ideal for fittings as it is easy to work with to create both standard types of fittings as well as custom fittings if and when required. This can be difficult to do with other alloys or other types of materials.