In general, you will note 7075 T6 aluminum in use in many different areas. These will include an aerospace and aircraft components as well as in gears and in valves. You will also find it used in a wide variety of common applications in shafts in vehicles and even in gears and keys, all because it is so durable and strong. It is also use by the United States military in the development of some weapons and firearms.

The most important thing to remember about this alloy is that it is incredibly strong. It provides one of the highest strength to weight ratios, which is why it is so widely used in the aerospace and airplane industries as well as for automobiles. These are all applications where strength needs to be paired with a lightweight, corrosion resistant aluminum alloy.

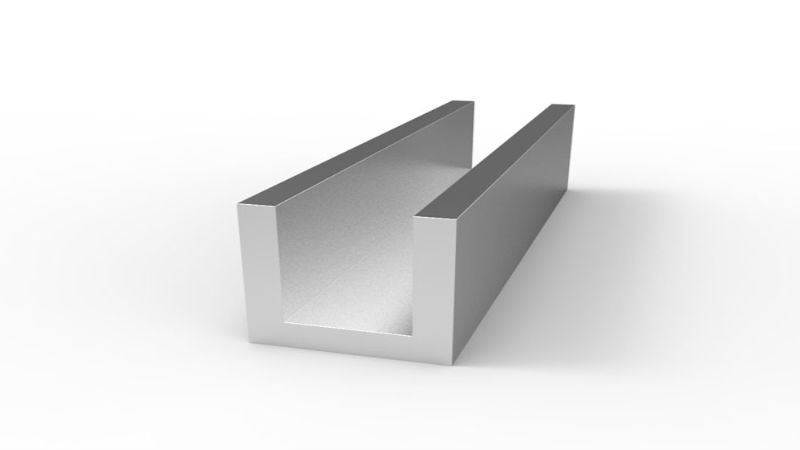

For most applications, 7075 T6 aluminum can be used as an aluminum bar, plate or rod, and it can be cold finished or extruded. Top suppliers of this aluminum will produce a very fine grain, which in turn provides uniformity through the alloy. The one drawback to this aluminum alloy is that it is not weldable, but it can be bonded.

The Benefits

The primary component with the aluminum in this alloy is zinc. There are also additional components in the alloy including magnesium, chromium, iron, manganese and copper. As it is designated as T, it means it is a thermally treated alloy. The heat treating occurs during the artificial aging process, producing the strongest and most durable alloy in the 7075 line.

Some of the 7075 T6 aluminum used in specific applications such as aerospace and aircraft manufacturing goes beyond just the thermal treatment process. This actually allows the manufacturer or mill to stretch the metal through a specific and controlled process during aging.

This creates another designation, known as 7075 T651. While it is not as strong and having a lower tensile strength and yield strength, it also has lower surface stress, which provides additional options for specific types of uses.

While 7075 T6 aluminum is not as corrosion resistant as some of the aluminum alloys, it is still considered a top option to use. It can be machined, so it is found in some of the small parts and components on aircraft as well as the larger structural components, particularly in those components where exposure to water or corrosive elements is not a factor.