The process by which bags and packages are produced on packaging lines will vary based on the type of machine, the configuration, and also the type of bag. Understanding how these machines work is essential in choosing the right plastic bag sealing machine for any operation.

Types of Equipment

In general, there are two distinctive types of machines that are used for commercial bagging operations. One is a vertical bagger, which uses film to create each bag, fill it with the product to the desired level, and then seal the bag all in one fluid motion. These machines can operate at speeds of up to 180 bags per minute (BPM) depending on the machine, the size of the bag and other factors.

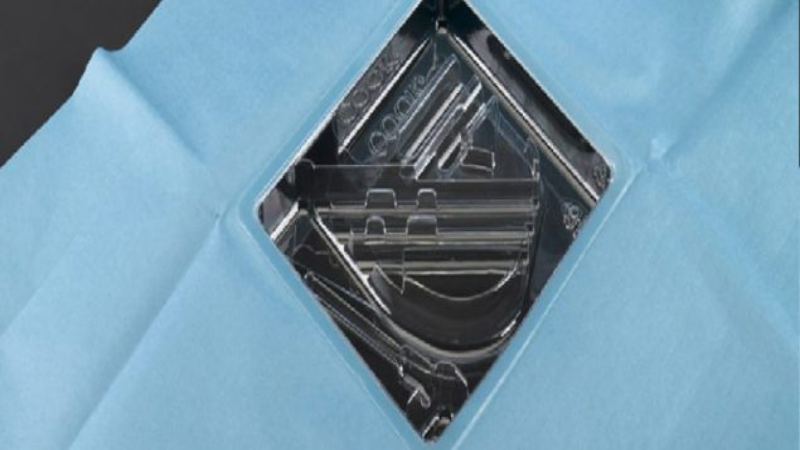

The other option is a machine that uses actually bags, also known as pouches, that are pre-made. This eliminates the need for the actual formation of the pouch and also provides the option for a wider width and length of pre-made bags to the used on the same machine.

These machines can operate at speeds of up to 45 pouches per minute, which will again be determined by the size of the bag and other factors. These are generally designed to fill smaller bags than vertical baggers, and may have maximum filling weights of one kilogram.

Options to Consider

With the use of the second option, the pouch machine or plastic bag sealing machine, there are several features or options that can be added for specific types of bagging requirements. This may include the need for zippered closures on bags, which are often found with spices, nuts, cereal, snack foods and other types of products.

Date code printers can be mounted in the units, printing the required best before dates on the bags. Preset computerized controls on the front touch pad of the machine can allow the operator to switch between printing and bagging sizes and programs, ensuring the date code is always in the correct location.

Additional features can include a product settler feature, which gently moves the bag and contents while filling to allow for accurate filling to specific weight requirements. This is an essential feature for bulky types of items such as cereals.

Finally, to add to the features or options, a plastic bag sealing machine may also offer gas injection. This allows controlled atmosphere to be injected into the bag during the sealing process, adding to product protection and storage optimization in a low oxygen environment.