Tungsten carbide is an alloy used to create construction tools and components for manufacturing. A unique feature of this alloy is its ability to be recycled and melted down for reuse. Scrap carbide recycling reuses metal left over from manufacturing and turns it into a workable material used to make other products and tools.

Types of Scrap Carbide

Different kinds of scrap carbide can be used for recycling and industrial production. Each kind has a varying tungsten content, usually between twenty and ninety percent. This determines its purity content and eventual use before recycling and usage. Tungsten carbide scrap takes two predominant forms: hard scrap, consisting of shavings and leftover metal scraps, and soft scrap, also known as sludge, consisting of tungsten carbide grit mixed with water in various combinations. While both kinds are used in manufacturing, they will have a different sales price based on their purity.

The Recycling Process

Scrap carbide recycling begins with manufacturers selling their excess carbide scraps. A buyer pays for the scraps and perform a purity test to determine the tungsten content of the batch. Most buyers look for a specific variety of carbide, including hard scrap or carbide sludge, but many accept offers based on the results of the purity test. After this test is completed, the buyer melts the carbide into one solid batch, combining it with other scraps and metals.

Some of the metal is sold to manufacturers, but the buyer may use it for their own manufacturing jobs. If a business is interested in reusing their scraps for an upcoming order, they may commission the buyer’s shop to create new tools for them. This service keeps recycling and reuse services within one shop, making the process more convenient and customized.

Industrial Use

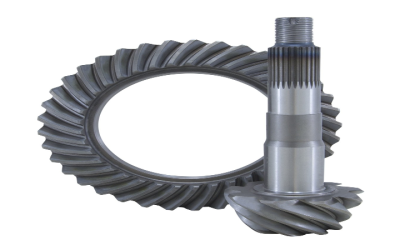

Scrap carbide recycling is used to create new parts for industrial machinery. Alloys including tool steel use tungsten carbide to make new tools and parts out of broken or scrapped carbide parts. If a component breaks and requires a replacement, it can be melted down and reforged into a replacement along with other steel scraps. Another use for tungsten carbide is inclusion in other alloys. Tungsten reinforces and strengthens other metals, making it an excellent addition to industrial grade metals.