According to the method of displacement pumps are categorized into positive displacement pumps and centrifugal pumps. A positive displacement pump traps a fixed amount and forces the trapped volume into discharge pipe

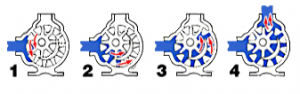

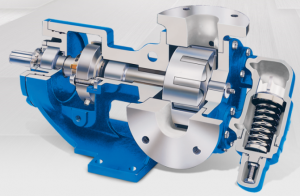

Internal gear pump consists of a rotor ad idler. Liquid travels between them through “gear-within-a-gear” principle. Pump head forces the liquid to move out of discharge port. A seal is formed between the discharge and suction ports. This pushes liquid out of the discharge port.

Benefits of the internal gear pump:

- Easy on maintenance with two moving parts and one stuffing part.

- Works well for high viscosity liquids

- Constant flow and is not affected by pressure

- Operates well bidirectionally

- NPSH requirements are quite low as compared to other pumps

Typical application areas for these pumps include:

-

Fuels And Lube Oils

-

Alcohols And Solvents

-

Asphalt, Bitumen, Tar

-

Resins And Polymers, Pu Foam

-

Food Industry (chocolate, Starch)

-

Inks, Pigments, Paints

-

Soaps And Surfactants

-

Glycol

-

Base Oil, Additives etc

To know more about Viking internal gear pumps: visit: http://www.idexindia.in/viking-pumps/internal-gear-pumps/. Alternatively you can call IDEX India on 1800 267 9955 or email them on info.fmt@idexcorp.com