The choice of raw materials for folding carton manufacturers can be daunting these days. The differences in the properties of paperboard and their applications are creating interesting subtleties in today’s economy. There are several key factors that influence the choice of substrate for cartons and include print performance, design features and requirements, sustainability, product protection, and overall value.

Folding Carton Manufacturers and Print Performance

Although some companies still use traditional print technologies such as flexography and sheet and web offset lithography, many folding carton manufacturers are beginning to turn to laser imaging and digital printing. Packaging substrates are able to perform well regardless of the printing process. Aqueous, solvent-based, and oil-based inks are used and cured by a variety of mechanisms, such as UV printing and UV coating, infra-red and electron beam technology. Often more than one printing process is used in a single carton.

Design Features and Requirements

The choice of substrate can also be greatly influenced by the size and style of the carton. One material may be favored over another depending on the use of windows, panels, filling line requirements and opening and closing of the carton. Grain orientation also plays a role as such properties and tensile strength and stiffness are favorable in one direction whereas tear strength excels in the opposing direction. The density, fiber and forming method of each material determine the proportional difference of these factors.

Eco-Friendly

This is becoming increasingly important in the packaging substrate decisions made by folding carton manufacturers folding carton manufacturers. More and more they are looking to renewable materials, certified fiber, recycled content and the biodegradability and compostability of their cartons to be more environmental friendly.

Product Protection

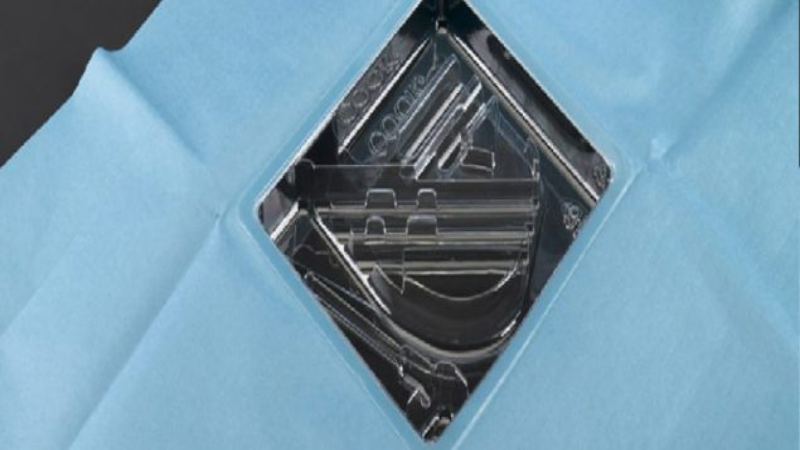

This is important as both the contents and the package must withstand the demands of distribution through filling, packing, palletizing, transportation, retail and consumer handling. Packages which are damaged can result in products which cannot be sold, thereby taking a great toll on the bottom line. Such products as pharmaceutical, health care and electronics all require different types of protection against humidity, temperature, shock and other factors.

Overall Value

Customers expect certain benefits for the price they paid for a product. Packaging solutions need to meet the type and quality of a product for customers to purchase and remain loyal to a given product.