The origin of folding cartons dates back to the early 19th century. It is the product of early consumerism and packaging interests. Originally, the intent was for such boxes to contain only the high-end products. Only after the National Biscuit Company (NABISCO), introduced its line of UNEEDA soda crackers in 1896/97, did the universal commercial use of the folding carton come to the forefront. After that, product manufacturers began to rely on cartons to provide them with the containers they needed to help display, promote and sell their products

The Introduction and Production of a Folding Carton

In the beginning, the folding carton was produced by hand. Manufacturers or suppliers used manual labor to produce the container. Some mechanization and, therefore, mass production of the process came out of an error involving a printing press in at Robert Gair Company, on Reade Street in Manhattan, in 1879. Gair (1839-1927), an immigrant from Edinburgh Scotland, discovered during this incident that if he cut and creased paperboard in a single operation, the result was a prefabricated container. His company grew and he subsequently moved it to premises near the Brooklyn Bridge on Washington Street in Brooklyn.

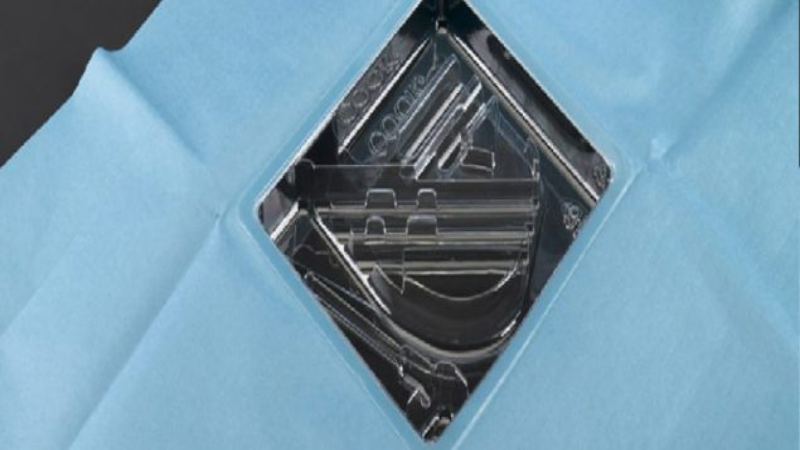

Today, machinery called “cartoners” also known as carton-making machines, produce the desired shape, size and thickness of folding cartons. Most machines handle the complete process from beginning to end including:

* Feeding sheets of paperboard into the machine

* Printing the desired design and other items onto the material

* Laminating the material

* Cutting the material into the right size and shape

* Folding the box

* Piling them into pre-ordained groups

* Shipping them off to distributors or manufacturers

Some machines do more than ship the product to a distributor or manufacturer. They turn the folded carton into an actual container, glue or otherwise stick the bottom together, sealing it. Such machinery may even fill the box with the specified product.

Folding Cartons

These containers come in a comprehensive variety of packaging types. Companies may focus on one type over another. Among the available kinds of cartons are:

* Boxboard – more lightweight, this material is ideal for packaging. It provides the basis for cereal boxes, shoes boxes, medicine containers, ice cream and toothpastes, to name a few

* Containerboard – usually for those containers intended to hold large and heavy items e.g. stoves, refrigerators, televisions, computers

* Greyback duplex board

* Folding Boxboard(FBB)

* White back duplex board

* Kraft liner board

As inexpensive packaging, such packaging materials continue to dominate the field. With the rise of environmental concerns, packaging companies re-evaluated their work processes and techniques. They have begun to recycle the material they produce and the waste left over. By doing so, and encouraging various forms of environmentally sustainable practices in their industry, they are making sure that their industry can continue to make folding cartons capable of meeting the demands of the market, government restrictions and public opinion.