For prototypes, retrofits and those impossible to find aluminum trims and moldings, it may be necessary to work with an aluminum company to produce your own custom aluminum extrusion.

Is it Really Custom?

If you are considering the feasibility of a custom extrusion, you may first want to talk to the engineering team at a top aluminum supply company. These companies work closely with mills and extruders offering custom aluminum extrusion services, allowing them to track down an existing die that may be ideal for the shape you need.

This can be very helpful for several reasons. First, it will decrease the cost of creating a die to make the extrusion. Second, it will ensure that the die design produces an extrusion shape that stands up and doesn’t have the possible design flaws with a new extrusion. Last, it can help to speed up the time from the order to the extrusion being available.

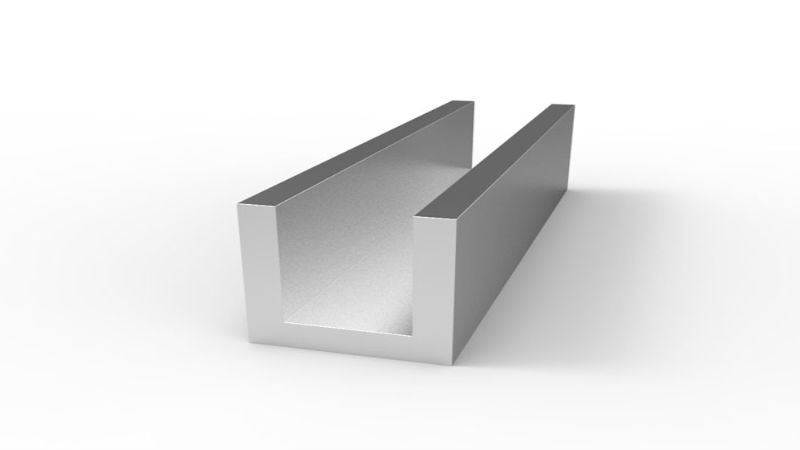

Consider the Shape

It is possible to create just about any shape with a custom die. However, not all shapes are going to be the best option just because they are possible to create. The more complex the shape is, the more challenging it will be to have the quality control throughout the run.

Simple shapes are going to provide higher quality, less waste and lower costs. Creating uniform wall thicknesses rather than thick and thin walls is a good example of how to simply a shape for better overall quality.

Working with an aluminum supplier with experience in providing custom aluminum extrusion services for their customers early in the design process is critical. This will ensure your team doesn’t spend time and money on designs that aren’t going to be feasible and effective to produce. It will also help in determining if a standard extrusion could be a possibility with some minor design changes.