“Necessity is Mother of All Invention”, it seems Egyptians understood it better & thus they invented the first pump in 2000BC, which was a manual hand operating pump & used for raising the groundwater. Since then pumping technology has undergone many revolutions & inventions. Today pump industry is classified in to majorly two segments – Centrifugal & Positive Displacement pumps. Both the technologies find their selection primarily based on the application.

There is another technology which is a hybrid & known as AODD (Air operated Double Diaphragm). An AODD pump resembles the characteristics of a centrifugal pump when it comes to capacity versus discharge head & that of a positive displacement pump when displacing fluid while working against the pressure. That’s why it is best known as sealless semi positive displacement pump.

AODD pumps runs on compressed air, are self-priming, can run dry & handle solids making it a good choice for moving abrasive, corrosive, toxic, shear sensitive, flammable fluids. It finds its presence in Chemical, Paints, Ceramics, Pharma, Oil & Gas, Automotive, Waste Water, Mining & many more industries.

It used to be considered as a last resort but in recent years has gained wide acceptance across all the industrial segments & even has become first choice in place. Warren Rupp Inc.,(IDEX Corporation) since its inception in 1965 has evolved the AODD pump with introduction of first bolted air operated diaphragm pump 48 years ago. Since then it has been holding a leading position in this market & has the broadest range of pumps.

How it Works

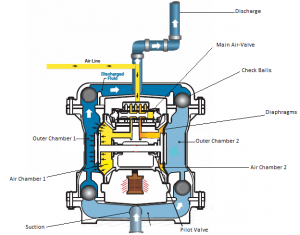

Air operated diaphragm pump has two main components – Wetted & Non-Wetted. As the name implies wetted part remain in contact with the fluid & non-wetted is the work house of the pump wherein compressed air is supplied. The wetted component consists of Suction & Discharge  Manifolds, Outer Chambers, Diaphragms, Check Valve(NRV), Check Seat. Non-wetted part of the pump comprises of Air-Chamber, Main Air-Valve & Pilot Valve. The diaphragms are connected with diaphragm rod & these diaphragms act as separation between air & fluid.

Manifolds, Outer Chambers, Diaphragms, Check Valve(NRV), Check Seat. Non-wetted part of the pump comprises of Air-Chamber, Main Air-Valve & Pilot Valve. The diaphragms are connected with diaphragm rod & these diaphragms act as separation between air & fluid.

When compressed air is supplied to centre section(air chamber) the Main air valve directs the air in to chamber 1 where air exerts pressure at the back of the diaphragm, which makes the diaphragm movement to the left. While doing so suction & discharge check balls in opposite chambers gets lifted up & thus making the pressure less than atmospheric in liquid chamber 2. Fluid enters in to outer chamber 2 & once this stroke is completed the pilot valve which remains in contact with inner diaphragm plate enables the exhaust of air & simultaneously supply of air in to air chamber 2. Fluid is discharged through outer chamber 2 & fluid enters in to outer chamber 1. This cycle is repeated to get the desired flow rate.

Features

Air-Driven – Intrinsically safe

Self-Priming

Sealless

Variable Flow & pressure

Runs Dry without damage or heat build up

Deadheads against closed discharge

Portable & Submersible

Fully Groundable

No need of pressure relief valve

Handle solids

AODD pump are available in a wide range of MOCs – both Metallic (Al, SS, CI, Hastelloy) & Non-Metallic(PP, PVDF, Acetal) & similarly diaphragms (PTFE, Nitrile, Buna, Santoprene, EPDM, Hytrel) making it a suitable product with almost all fluids covering entire industrial segments. Since there is limitation to compressed air pressure, the working pressure of the pump is also safely limited. Thus making AODD best suited for on-demand intermittent requirements. You can also follow them on LinkedIn.